About Combiplus Steam Boiler

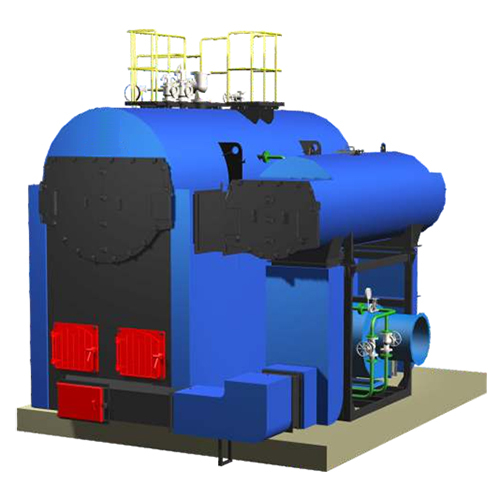

COMBIPLUS is a water cum smoke tube type package steam boiler, which can fire solid fuels like coal, lignite and wood. The fuel is charged through a charging door to keep the fire going. COMBIPLUS is designed to provide low cost heating with minimum operational complexity.

Unique design features

The best of two worlds (combining hybrid and integral furnace boiler technologies) Combiplus blends the best of two different boiler technologies, to offer a configuration which combines all the benefits of hybrid boilers like fuel flexibility, as well as the inherent ruggedness and compactness of integral furnace boilers.

How Combiplus scores over the hybrid boiler...

- Up to 90% reduction in refractory.

- Up to 40% reduction in footprint.

- Up to 80% reduction in site work.

- Flexibility to burn a wide variety of solid fuels - fossil and biomass.

- Quick start up time.

OPERATING RANGE:

- Capacities : From 0.5 to 6 TPH

- Firing fuels : Coal, lignite, wood and wood breeket,

- Pressure : From 10.54 to 17.5 Kg/cm2 (g)

Exceptional Efficiency and VersatilityCombiplus Steam Boiler supports multiple fuel types-oil, gas, wood, or coal-making it adaptable to varying operational needs and cost considerations. Its robust glass-wool insulation minimizes heat loss and maximizes energy efficiency, offering significant long-term savings for industrial steam users.

Built for Safety and Reliable OperationEngineered with state-of-the-art pressure and temperature safety valves, the Combiplus boiler puts operator safety at the forefront. The automatic digital control panel ensures user-friendly monitoring and operation, reducing manual intervention and optimizing operational stability.

Easy Installation and MaintenanceDesigned for floor mounting with compact dimensions (700 mm x 1200 mm x 1500 mm), this boiler integrates seamlessly into existing industrial setups. Its straightforward layout and mild steel construction enable easy routine maintenance, boosting uptime and operational reliability.

FAQ's of Combiplus Steam Boiler:

Q: How is the Combiplus Steam Boiler installed and where can it be used?

A: The Combiplus Steam Boiler is floor-mounted, allowing for stable installation in industrial environments. It is suitable for a wide range of industries, including dairy, pharma, chemical, and food processing, providing flexible steam generation solutions for various operational requirements.

Q: What type of fuel does the boiler use and how does this affect its operation?

A: This steam boiler is designed for multi-fuel compatibility, operating efficiently on oil, gas, wood, or coal. Fuel consumption varies by type-from 3-12 kg/hr for solid fuels to 2-5 L/hr for liquid fuels-so customers can choose the most cost-effective and locally available options.

Q: When should I perform maintenance, and how easy is it?

A: Thanks to the boiler's compact design and accessible components, routine maintenance is straightforward. Maintenance schedules typically follow industry standards-regular inspections of valves, the control panel, and cleaning to ensure optimal performance and longer lifespan (up to 15 years).

Q: What safety features are included with the Combiplus Steam Boiler?

A: This model incorporates advanced safety features, including both pressure and temperature safety valves. These mechanisms help prevent over-pressurization and overheating, ensuring safe and reliable operation during continuous industrial use.

Q: How does the automatic digital control panel benefit users?

A: The integrated automatic digital control panel allows for effortless monitoring and operation, reducing the need for manual adjustments. This increases operational efficiency, optimizes steam output, and ensures safety through real-time data insights.

Q: What are the key benefits of glass-wool insulation in the Combiplus Steam Boiler?

A: The glass-wool thermal insulation minimizes heat loss, improves energy efficiency, and helps maintain consistent steam supply. This leads to reduced energy costs and better performance, especially in environments where energy conservation is crucial.